3D Printing Industry reports on a fascinating experiment carried out at Virginia Polytechnic Institute and State University (VT).

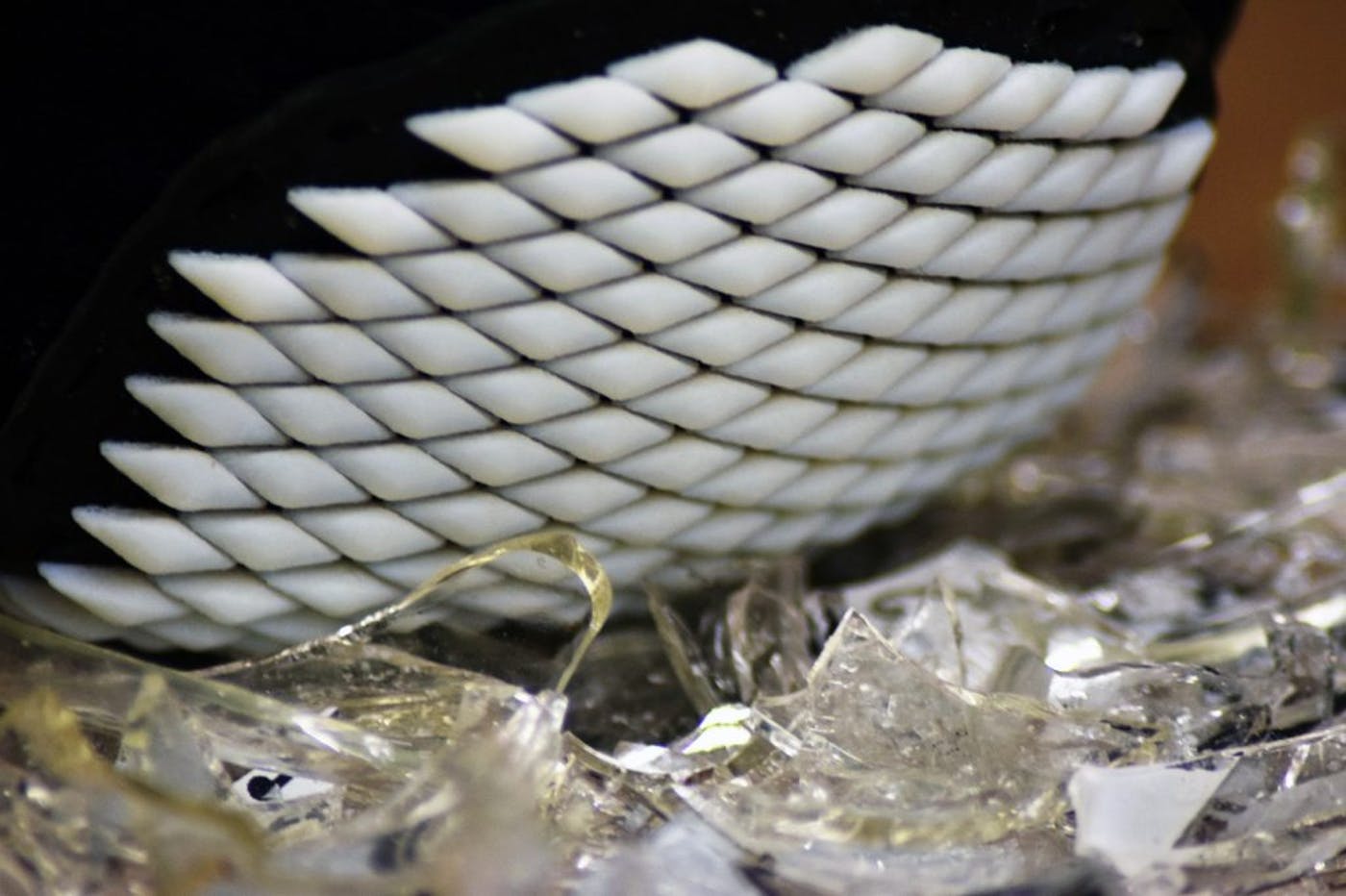

Associate Professor at the Department of Mechanical Engineering Ling Li “has developed 3D printed flexible scaled armor inspired by the chitons, a group of marine mollusks.” With this study, Professor Li’s team “sought to improve on the rigid structures used in man-made armors, which typically compromise on flexibility and maneuverability. Thus, using parametric computational modeling and multi-material 3D printing, flexible, scaled, ceramic armor components were created.”

Professor Li explains the choice of armor inspiration: “most mollusks have a single rigid shell, such as the abalone, or two shells, such as clams, but the chiton has eight mineralized plates covering the top of the creature and around its base, it has a girdle of very small scales assembled like fish scales, providing flexibility as well as protection…we studied the [girdle scales] in a very detailed way. We quantified its internal microstructure, chemical composition, nano-mechanical properties, and three-dimensional geometry. We studied the geometrical variations of the scales across multiple chiton species, and we also investigated how the scales assemble together through 3D tomography analysis.”

The team was therefore able to develop “a parametric 3D modeling methodology replicating the geometry of individual scales. This was used to assemble individual scale units on flat or curved substrates, which could then be additively manufactured.”

Professor Li concludes: “with these physical prototypes of controlled specimen geometries and sizes, the team conducted direct mechanical testing on them with controlled loading conditions. Following these tests, [the team was able to] conclude the dual protection-flexibility performance of the biological armor system would be suitable for the production of 3D printed protective gear such as kneepads.”

Image and Quotes Courtesy of 3D Printing Industry